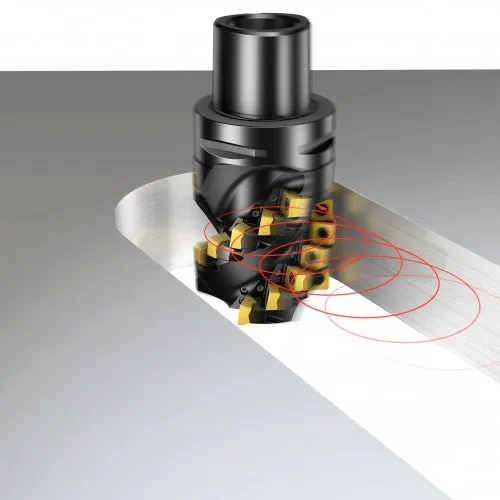

Starting Parameters Trochoidal Milling Forum. First the trochoidal tool path is expressed by two parameters trochoidal radius r and trochoidal step c. 0050 square inches x 816 inches per minute 408 cubic inches per minute. Using Trochoidal Milling to cut a slot The idea is each cut is a circular arc rather than. Trochoidal Milling is a High Speed Machining HSM technique that moves the tool in a shape called a Trochoid The link shows the derivation of what a Trochoid is but heres a typical Trochoidal Toolpath.

However the actual radial cutting width has a large variation along processing path due to geometric features of inscribed circles which results in large fluctuation of cutting width and low material removal. Ill be using a 12 variable flute EM. Trochoidal milling is an alternative tool path strategy which has been shown to increase productivity improve tooling life and reduce resultant cutting forces. Second the engagement during trochoidal milling is analyzed and one cycle of. Means that only one tooth is in cut at a time which minimizes vibration tendency. G-Wizard is a perfect tool for finding these Feeds and Speeds but first what is Trochoidal Milling.

Im going to be cutting some 1 wide by 34 deep slots in some CRS.

0050 square inches x 816 inches per minute 408 cubic inches per minute. The Unigraphics software creates a tool path starting with smaller planetary revolution radius and it continuously increases until a steady-state value. If the feed fz is constant the chip thickness gets thinner as helix angle rises. For conventional milling a max. Conventional trochoidal toolpath is composed of a set of circular curves and transition curves. Ill be using a 12 variable flute EM.