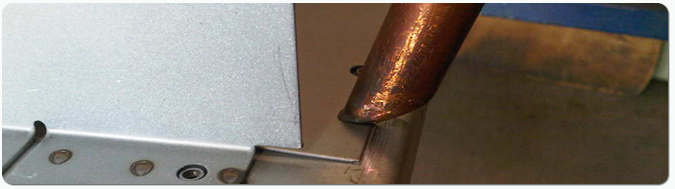

Spot Welding Stainless Steel Tips. Pro Tip for Best Practices. It is highly important to clean the metal before any type of welding and cleaning helps get rid of all the dust and other particles before welding stainless steel. Thats not to say that you cant weld stainless with rocker type welders its just that it will be harder to set up and difficult to obtain pressure with the longer arms. One way to prevent warping when welding stainless-steel is to clamp a piece of brass or copper behind the seam of the weld.

Spot welding of stainless steels is usually carried out on thin sheets. For more heat amperage output use shorter tongs. Metallographic studies and salt-spray testing have never revealed any sensitization or short coming in the corrosion resistance of our spot welded stainless steel assemblies. Keep the toolset separate to clean the stainless steel before welding. Use for steel and stainless steel only. The Spot welding is commonly being used in automobile industry where it is used to weld the sheet metal forming a car.

Use for steel and stainless steel only.

Any tool with residual carbon may contaminate the stainless steel and leads your final product to. Resistance welding is not recommended for aluminum copper or copper alloys. The TITE-SPOT Pliers has the welding tips sharpened to 316 diameter when new. The actual time required to weld the pin is about 50 milliseconds and no marking or discoloration occurs on the front of the dime. Keep the toolset separate to clean the stainless steel before welding. The tips can be allowed to fatten to 14 diameter before they need to.