Hoop And Axial Stress. Longitudinal or axial direction. It is the normal stress parallel to the z-axis. Axial stress a normal stress parallel to the axis of cylindrical symmetry. Axial stress is the stress along h.

Stress in Axial Direction. The stress in axial direction at a point in the tube or cylinder wall can be expressed as. Each of these stresses can be calculated from static equilibrium equations. This is known as the axial or longitudinal stress and is usually less than the hoop stress. Hoop stress is caused by Internal pressure. Because of their directions the stress σ1 is called the circumferential stress or the hoop stress and the stress σ2 is called the longitudinal stress or the axial stress.

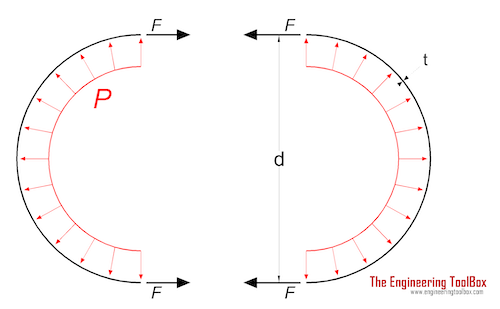

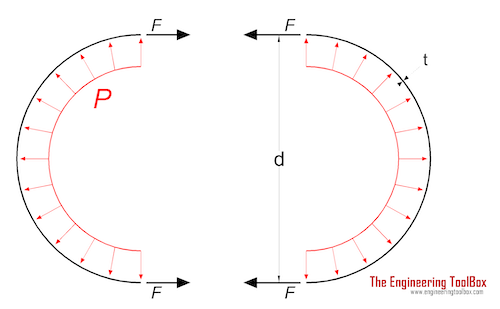

This is the stress which is set up in resisting the bursting effect of the applied internal pressure and can be most conveniently treated by considering the equilibrium of the cylinder.

It is also known as longitudinal stress. Longitudinal Stress Thin Walled Pressure Vessel. The maximum hoop stress always occurs at the inner radius or the outer radius depending on the direction of the pressure gradient. σ h hoop stress MPa psi p internal pressure in the tube or cylinder MPa psi. The repository model can be considered to be equivalent to such a situation and hence the equations for the stresses at radius r and the radial displacement of the inner surface y are. Piping Hoop Stress The Hoop stress is conservatively calculated as.